Welcome to Greenlan Water Treament|GREENLAN

| Availability: | |

|---|---|

|  |  |  |

Product Introduction:

CTSALT disc film drying crystallization system is a combination of dryer with MVR technology to realize indirect heating.

Steam through heat conduction to heat the disc to solidificate the waste liquid on the disc and finally through the scraper to scrap off the solid salt automatically .

The water in the wastewater is separated from the waste to obtain crystal-clear distilled water with a COD reduction of up to 99%.

Moisture content is low to 10%.

Compared with other wastewater dryer, its merits special heat transfer surface is significantly higher, smaller space requirements at the same time, low heat loss, without any consumable;

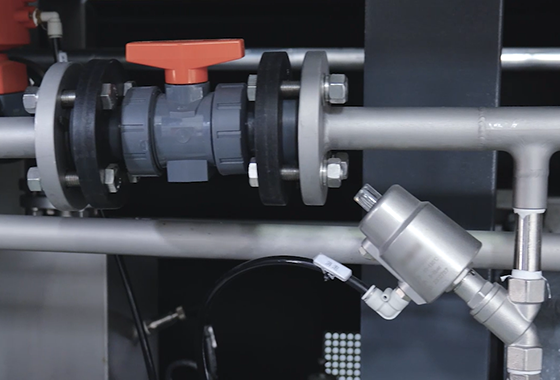

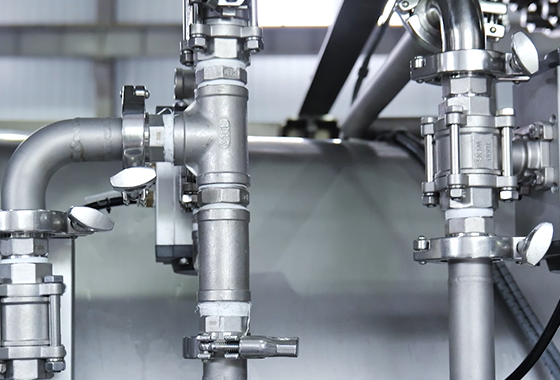

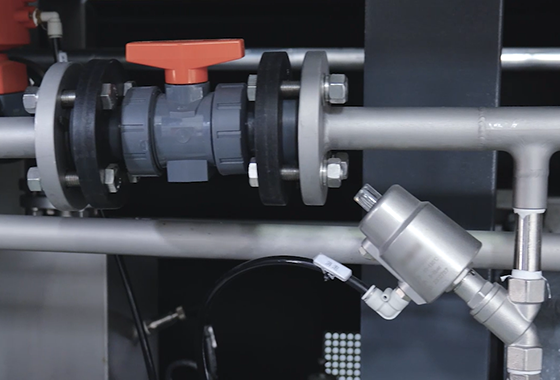

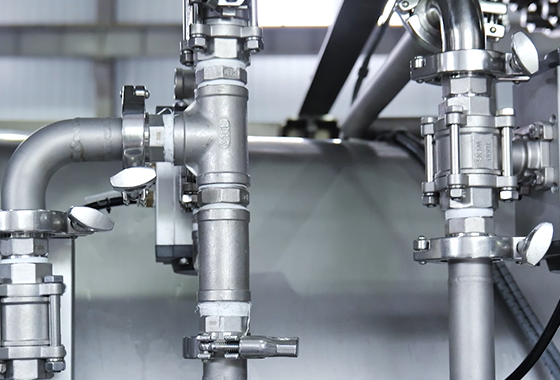

According to the customer's water quality, choose different materials, such as: 316L stainless steel or special stainless steel material resistant to corrosive liquid, 2205, 2507 or titanium, etc.

Main Features:

Use low power consumption, realize the wastewater drying, without any external cooling energy. High distillation drying speed and short heating time,

Due to the wastewater dried on both sides of the disc, so the heat efficiency is high. Its compact design, less heat loss, thermal efficiency can reach more than 80% to 90%.

The cloth disc distillation drying crystallization system can directly distill the dry liquid and scrapes the residue into powder, so it can eliminate additional processing steps and achieve distillation drying crystallization "in one step".

Oily waste liquid can be concentrated to paste (5-10% moisture content), common wastewater can be drying to powder particles (moisture minimum 1%).

PLC control system, fully automatic operation, can be 24 hours unattended continuous work.

Key Advantages

Low energy consumption: only use electricity, without steam or other auxiliary energy. Advantage is obvious in dealing with tons of water;

High efficiency; disc distillation process, compared with the tank evaporator, the efficiency increased by 20%;

Large processing capacity: multi-disc structure, theoretically the processing capacity can be N times unlimited expansion;

Heat transfer coefficient is high, the heating area is relatively small, the distilled liquid COD reduce more than 99%;

High energy efficiency ratio: compared with the traditional evaporator, the thermal energy efficiency ratio increased by 35%;

A wide range of treatment: food processing, high salt, high COD, high organic matter, high ammonia nitrogen sewage can be directly dried to solid crystals, direct discharge or reuse of water.

|  |  |  |

Product Introduction:

CTSALT disc film drying crystallization system is a combination of dryer with MVR technology to realize indirect heating.

Steam through heat conduction to heat the disc to solidificate the waste liquid on the disc and finally through the scraper to scrap off the solid salt automatically .

The water in the wastewater is separated from the waste to obtain crystal-clear distilled water with a COD reduction of up to 99%.

Moisture content is low to 10%.

Compared with other wastewater dryer, its merits special heat transfer surface is significantly higher, smaller space requirements at the same time, low heat loss, without any consumable;

According to the customer's water quality, choose different materials, such as: 316L stainless steel or special stainless steel material resistant to corrosive liquid, 2205, 2507 or titanium, etc.

Main Features:

Use low power consumption, realize the wastewater drying, without any external cooling energy. High distillation drying speed and short heating time,

Due to the wastewater dried on both sides of the disc, so the heat efficiency is high. Its compact design, less heat loss, thermal efficiency can reach more than 80% to 90%.

The cloth disc distillation drying crystallization system can directly distill the dry liquid and scrapes the residue into powder, so it can eliminate additional processing steps and achieve distillation drying crystallization "in one step".

Oily waste liquid can be concentrated to paste (5-10% moisture content), common wastewater can be drying to powder particles (moisture minimum 1%).

PLC control system, fully automatic operation, can be 24 hours unattended continuous work.

Key Advantages

Low energy consumption: only use electricity, without steam or other auxiliary energy. Advantage is obvious in dealing with tons of water;

High efficiency; disc distillation process, compared with the tank evaporator, the efficiency increased by 20%;

Large processing capacity: multi-disc structure, theoretically the processing capacity can be N times unlimited expansion;

Heat transfer coefficient is high, the heating area is relatively small, the distilled liquid COD reduce more than 99%;

High energy efficiency ratio: compared with the traditional evaporator, the thermal energy efficiency ratio increased by 35%;

A wide range of treatment: food processing, high salt, high COD, high organic matter, high ammonia nitrogen sewage can be directly dried to solid crystals, direct discharge or reuse of water.

Principle Description:

The wastewater is recirculated from the storage tank through the pump into the individual feed pipes, and each feed pipe transports the liquid to the side of the heated rotating disc.

Concentrate finished in a circle after the heating disc rotation evaporation, dry solid adhesion on the heating disc, and then scrapped through the knife scraper.

The drying degree of the final product can be affected by the speed of the plate, and the resulting dry waste is discharged from the equipment through an automatic discharge system, or the liquid can be concentrated to produce a semi-solid product.

Depending on the waste liquid characteristics of different industries, the products obtained can have different forms.

Principle Description:

The wastewater is recirculated from the storage tank through the pump into the individual feed pipes, and each feed pipe transports the liquid to the side of the heated rotating disc.

Concentrate finished in a circle after the heating disc rotation evaporation, dry solid adhesion on the heating disc, and then scrapped through the knife scraper.

The drying degree of the final product can be affected by the speed of the plate, and the resulting dry waste is discharged from the equipment through an automatic discharge system, or the liquid can be concentrated to produce a semi-solid product.

Depending on the waste liquid characteristics of different industries, the products obtained can have different forms.